-

CORPORATE

CORPORATE

-

WHAT WE DO?

WHAT WE DO?

- OUR PRODUCTS

- OUR SERVICES

- PRODUCTION & RD

- CAREER

- MEDIA

- CONTACT US

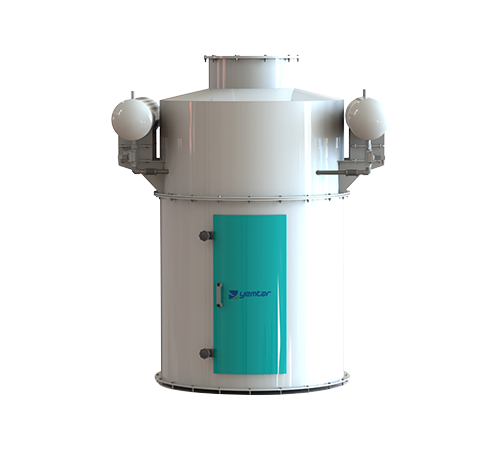

The mill filter is a filtration system generally used in crushing lines. This filter, which is mounted on the mill's lower bunker together with the mill, effectively holds the dust formed during the passage of the crushed product to the lower bunker. The system, supported by a vacuum snail type aspiration fan, drags the dust through the fan connected to the filter and directs it to the bag-shaped filter cloths. The pressurized air accumulated in the air tank is sprayed into the bags at certain intervals with the pulse valves, allowing the dust to be wiped and reused.

The mill filters, which are generally used in crushing lines, are installed together with the mill in the lower bunker, and the dust products produced during the passage of the broken product into the lower bunker are dragged by the fan connected to the filter and are held by filter cloths in the form of bags. sprayed into bags. Dust particles stuck in the bag are shaken and reused.

Total Area

Closed Area

Blue Collar Staff

White Collar Staff

Feed Production Systems That Feed the Future is a comprehensive approach that combines high quality standards and environmentally friendly production in animal nutrition by offering innovative solutions equipped with modern technologies and focusing on sustainability and efficiency principles.

SUBSCRIBE FOR FAIRS